Extruded Aluminum Corporation (located in Belding, Michigan, USA) has been our client for several years. As such, they knew who to call when they needed to upgrade their extrusion quench system.

As an extrusion and finishing company, we stand behind the results of our projects and love to showcase our clients.

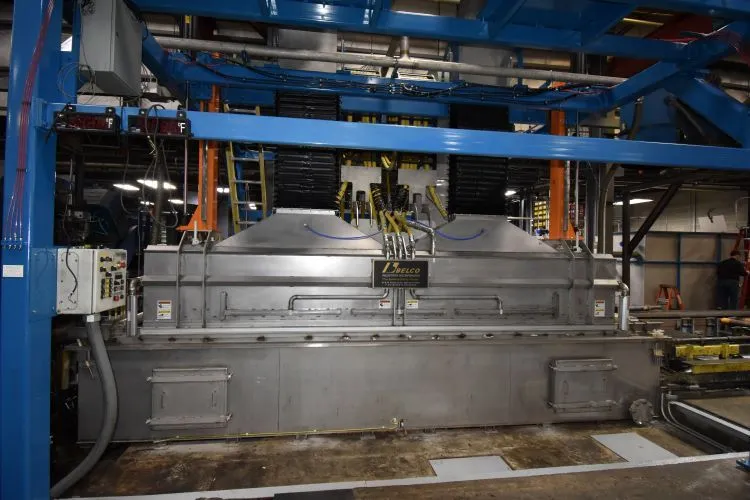

Here’s how our Belco quench system increased the production rate and reduced scrap for Extruded Aluminum Corporation.

About Extruded Aluminum Corporation

John Barret, Harvey Smith, and Bob Watson founded what is now called Extruded Aluminum Corporation in 1938. Since then, their facility has grown to cover 220,000 square feet with four extrusion presses. They also ship over 40 million pounds of every year!

Rick Kloska, the Operations Manager at Extruded Aluminum Corporation, said, “We extrude and fabricate aluminum for many different industries, such as aerospace, automotive, solar energy, marine, defense, trucking, electronics, etc.”

In 2019, Belco Industries started working with Extruded Aluminum Corporation to design and build a new quench system. The client chose our Extrusion Spray/Flood/Intensive Air Quench.

Client Goals

Extruded Aluminum Corporation needed to replace its cooling system with something more efficient. As with any system or piece of equipment, a decrease in efficiency also means a drop in production. That’s why it was essential for Extruded Aluminum Corporation to learn more about quench systems from Belco Industries.

Kloska said, “[We needed] to improve our recovery (scrap production) on our 12” press and upgraded cooling system. Our current cooling system was at the end of its life and was not efficient.”

Features and Benefits of Belco Quench Systems

The Belco Extrusion Spray/Flood Quench is a combination fully enclosed high-pressure water spray/low-pressure spray mist quench unit located at the press exit for cooling the aluminum extrusion profiles.

The quench allows multiple types of quench media to be applied as needed for the variety of extrusion profile shapes and speeds for excellent control of cooling on sides, top, and bottom.

It has the single operations of Intensive Air, Flood, High-Pressure Spray, Low-Pressure Mist, and Air/Mist.

Results: More Production and Less Waste

We met and exceeded the expectations set by Extruded Aluminum Corporation.

Kloska said, “The new quench equipment we purchased has increased production and reduced the amount of scrap that we produce. We are able now to get more repeatable results compared to the equipment we used to have.”

We couldn’t have said it better ourselves!

Conclusion

So, why did Extruded Aluminum Corporation choose Belco Industries?

Kloska explains:

“We have a long-standing relationship with Belco. We are able to communicate our needs and they will build what we ask for. They have great service and we are still able to add features to existing equipment to improve efficiencies.”

We love getting positive feedback from our clients and are dedicated to providing excellence in customer service. We also provide support to our clients after installing and integrating . That way, our clients always feel confident and empowered when using their new extrusion and finishing solutions.

Request a Quote with Belco Industries

Interested in a new quench system for your facility? To request an estimate, call Belco Industries at (616) 794-0410. As an , we’d love the opportunity to work with you and your team. Call today!