Quench Systems

Extrusion Water Quench’s

Water-Wall Style

The Belco Flood Quench is a standing wave-style water quench located at the press exit between the leadout table and the runout table. The standing wave-style quench allows the extrusions to be fully immersed as they travel through the trough. Spray nozzles are also located along the sidewalls of the trough to allow spray quenching on small, lightweight extrusions instead of running the full water wall. The independently controlled spray zones allow the operator to adjust the amount of spray based on the extrusion being quenched.

Intensive Quench

The Belco Extrusion Spray/Flood/Mist/Intensive Air Quench is a combination fully enclosed high-pressure water spray/low pressure spray mist quench unit located at the press exit for cooling the aluminum extrusion profiles. The quench allows multiple types of quench media to be applied as needed for the variety of extrusion profile shapes and speeds for excellent control of cooling on sides, top and bottom.

Extrusion Air Quench’s

Duct Cooling

Duct Cooling

The Belco Duct Cooling System consists of a main run of duct, outlet nozzles and a supply fan which blow high volumes of cooling air onto the extrusions.

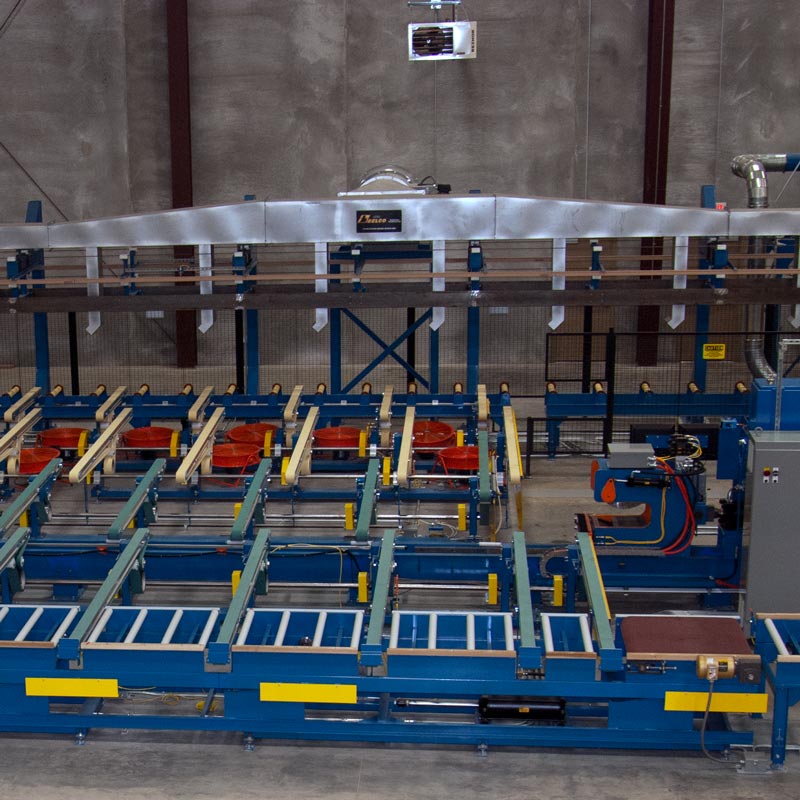

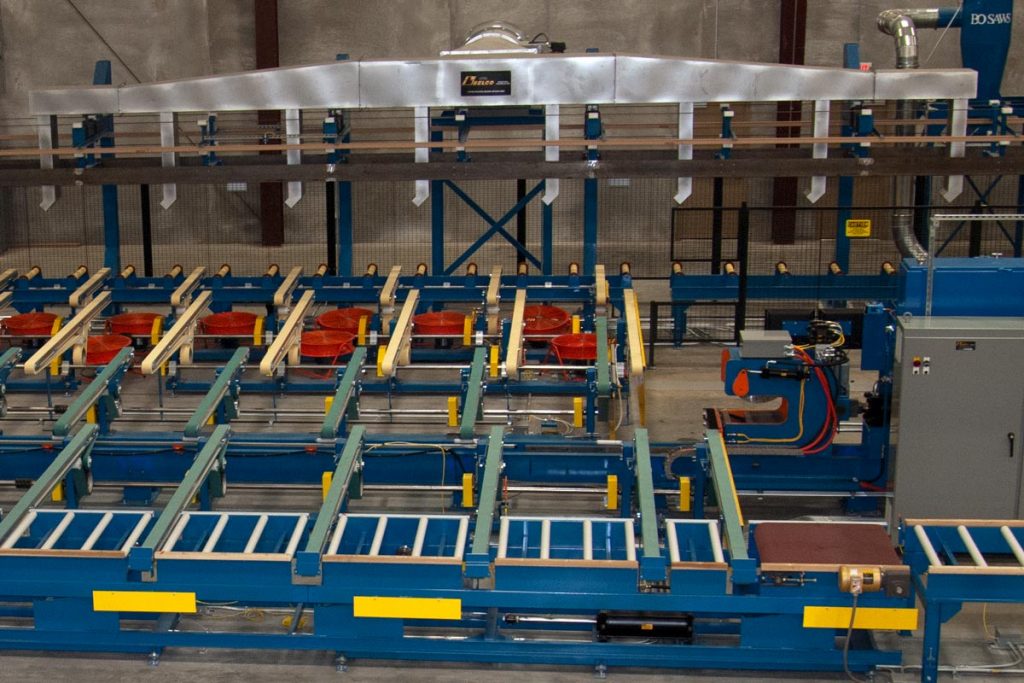

Under Table Fans

The Belco Under Table Cooling Fans are designed for high-velocity air on hot extrusions. The fans have a propeller-type blade and are designed to tilt in two (2) directions. The fans have a personnel guard on each side. Allen-Bradley variable speed drive will control the fan output air volume.